We have been working with precision metal turning for more than 60 years, and in 1985 we began specialising in the production of brass inserts used with plastic material overmoulding. In addition, we are ready to offer a variety of turned components to satisfy even the most sought-after production requirements, with innovative and personalised solutions.

Marangon is a company born in northeastern Italy where ingenuity and creativity contributed to the economic and human success of the people of Veneto. Even today, this spirit still fuels the will of this company to grow and improve day by day.

In 1961, Danilo Marangon opened the doors of a mechanical lathe shop that performed high-precision parts for a wide range of uses. In 1985, after intense activity and solid professionalism, the company was ready to choose to specialize in brass inserts, soon becoming one of the market benchmarks. The choice to process only brass allowed Marangon to streamline production, making it efficient and competitive. A choice of efficiency that has continued with the division of scrap from oil, fume abatement and a constant improvement of the production chain. All this has resulted in high quality production at an absolutely competitive price.

At present, Marangon srl is considered one of the most technologically advanced companies in the field of brass inserts, large-scale production includes: brass inserts for PPR, brass inserts for PE, brass inserts for CPVC, brass inserts for PPSU and PVDF, brass inserts for water filters, and brass fittings for transition between plastic and plastic or plastic and metal.

Marangon Danilo & C. boasts as one of its greatest successes that in the relationship of continuity with its customer, a relationship of trust that goes beyond the usual transaction that takes place between buyer and seller. Being part of its customers’ production cycle through its products has enabled the Vicenza-based company to establish a collaboration of total trust and esteem with them.

In 1982 the new headquarters of Marangon Danilo & C. opened in Montecchio Maggiore, which initially covered 1,000 sq. m., then with the acquisition of neighboring land has come to extend to the present day to a total area of 6,500 sq. m. , of which 4,000 sq. m. is occupied by production and 1,500 sq. m. by warehouses.

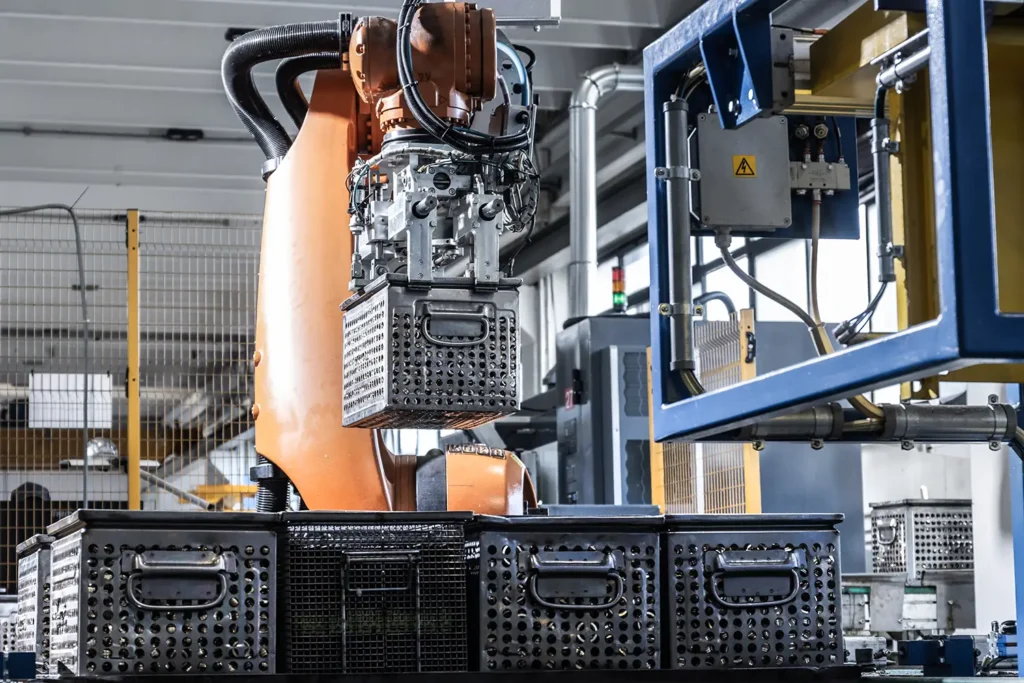

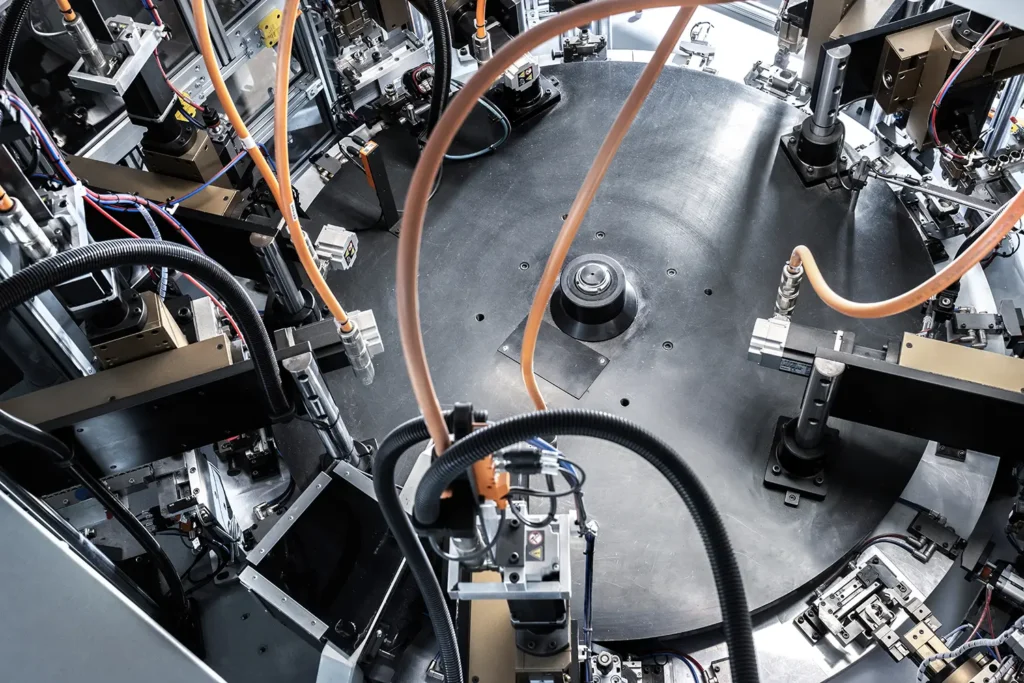

A machine park consisting of 29 state-of-the-art mechanical and numerically controlled multi-spindle automatic lathes, 7 numerically controlled single-spindle automatic lathes, modified alcohol washing machines with vacuum technology, and automatic packaging systems are the flagship of this company.

1961

Marangon Danilo is founded

with the first turning machine purchased where the founder worked during the day as an employee and in the evening as an entrepreneur.

1977

Maurizio and Nereo

The first sons began

working in the company,

at the time a mechanical turning shop that produced parts for various sectors.

1985

New headquarters

The company moved to Montecchio Maggiore in the industrial area

on a 1.000 sqm site.

1991

Development

of the company

Over the years, Flavio joined the company. Therefore, the firm was transformed into Marangon Danilo & C s.r.l.

1992

Mechanical cam

multi-spindle machines

The company already counts

around ten single-spindle

automatic machines.

In 1992, the first mechanic

multi-spindle GM35 turning

machine was purchased.

1998

ISO 9001 Certification

The company gets certified to ensure the highest quality standards.

2006

Start use of Industry

4.0 technology

Use of software for monitoring

of production

2010

Multi-spindle Machines

Purchase first CNC

multi-spindle turning machine.

2011

Third Generation

The 3rd generation Marangon is fully active in the family business

2014

Continuous Investment

The company has grown to cover an area of 8,000 sqm and invests in automation with the first automatic washing.

2021

60th Anniversary

The story continues.

We celebrate 60 years of activity with an operational development in continuous growth.

2022

38 employees for more than

35 operating machines

New CNC turning technology to offer more flexibility and service to customers.

2023

Headquarter renovation

Renovation and technological adaptation of the main office.

Construction new 600 sqm

office area.

2024

Constant increase in customer services with

automatic assembly lines